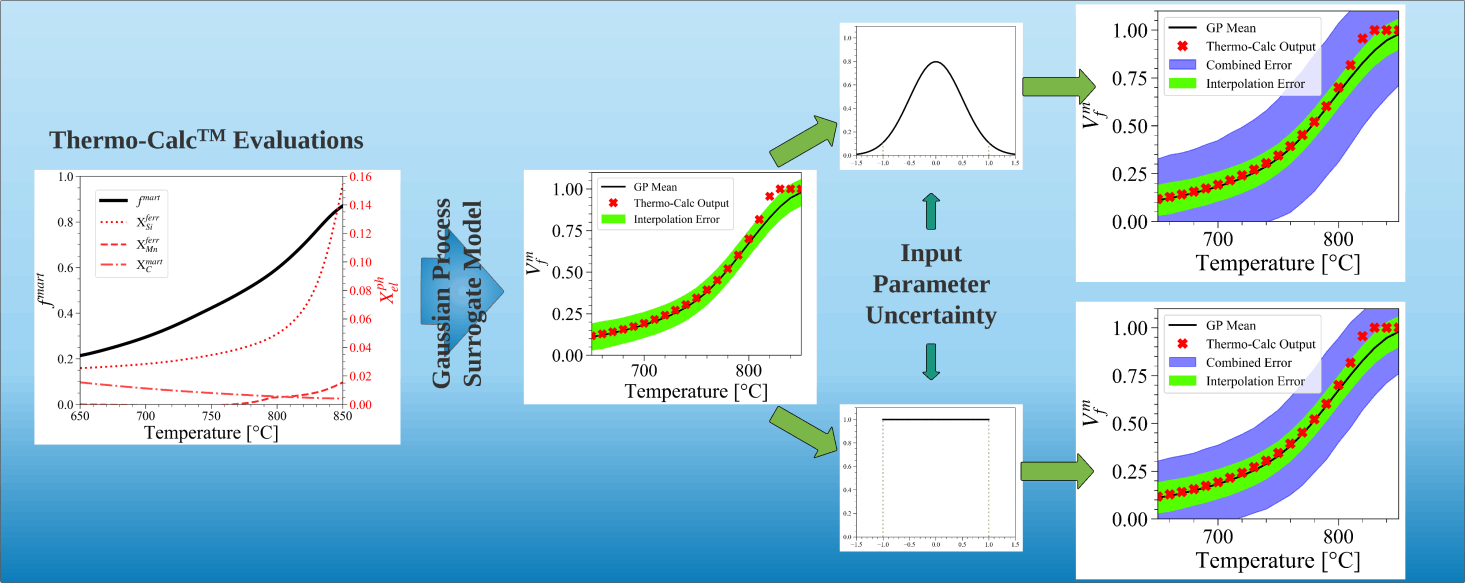

The aim of this project was twofold. Firstly, thermodynamic calculations are individually quick to complete, however, when doing many calculations, there can be a fairly substantial time cost. As such the aim is to reduce the cost of the calculations by using a cheap to evaluate surrogate model. The second aim is to remove the obstacle of license requirements. It is fairly common to have access to the Thermodynamic Database Licenses in a limited quantity (significantly less than would be required to run these calculations on a supercomputer). Therefore, in order to be able to leverage some of the more advanced materials design approaches it is necessary to be able to access the information in the Thermodynamic Databases, but use supercomputing resources it is necessary to construct surrogates.

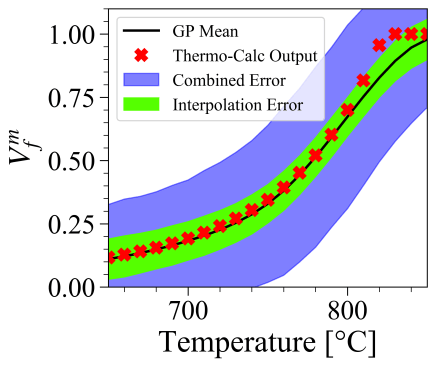

At the end of this process the aim was to have a surrogate model that is cheap to query and is accurate enough to replace the use of the actual Thermodynamic calculations.